Main menu

Aluminium composite. (ACM)

Use this list to explore more.

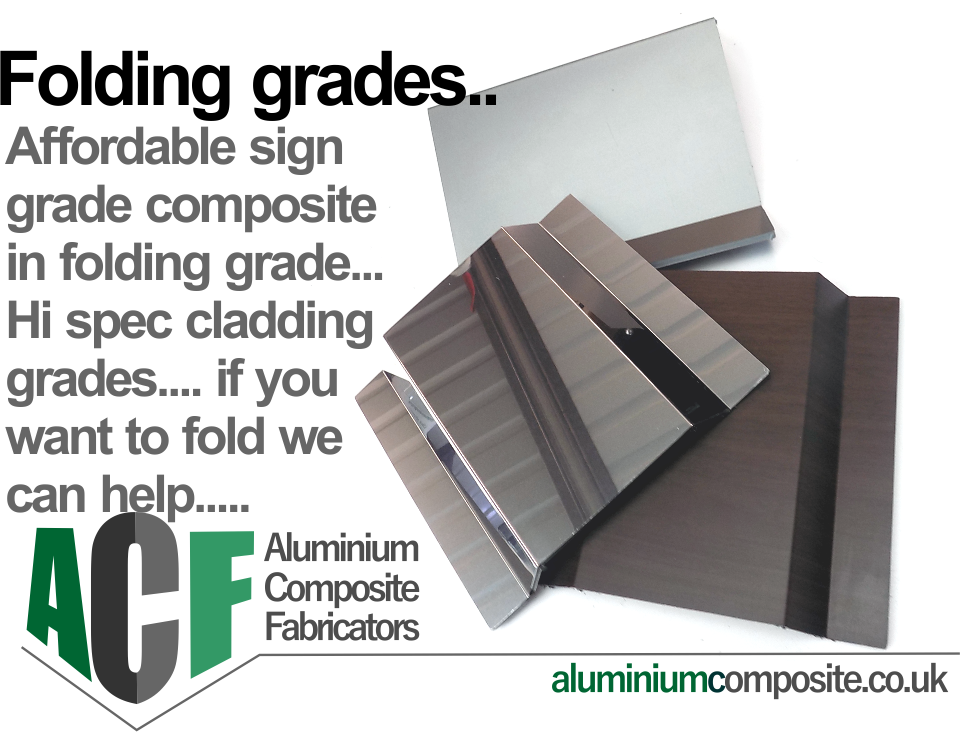

Folding grade aluminium composite.

Essential for structures.

Folding grade aluminium composites are specially formulated to allow for the production of clean, neat bend lines. Machined with specialist carbide tooling to a very precise depth this type of composite is a must for projects which require more than a simple flat shape.

The thickness of the aluminium skins used on either side of the plastic core; this is where the crucial difference lies. Folding grade composite must have skins which are a minimum of 0.3mm thick. Anything thinner should not be used as it simply doesn't have the strength and durability needed.

Ask any aluminium composite manufacturer and they will tell you that skin thickness is critical to proper folding results.

You could.

It is perfectly possible to machine fold lines into any grade of aluminium composite; even material with skin thicknesses down to 0.1mm can be scored and folded. The problem is the quality of the end result.

The aluminium skin on folding grade composite is designed specifically to add strength & rigidity to whatever folded part is manufactured from it. If you decide to save money and use thinner skinned composite instead you end up with a weak, wobbly structure. It might look the part but the structure you've just made is flimsy and liable to collapse under it's own weight when you attempt to move or install it.

Folding grade ACM gives you;

- Stronger fold lines

- More structural support

- Zero folding "weave"

- Confidence that the parts made are structurally stable

- Ensures compliance with manufacturer instructions

- Allows you to deliver a quality finish to the end user.

Folding grade composites can be supplied processes or as plain sheets. If you're looking for someone to work your own material then free issued customer ACM is something we work with all the time.